Introduction to Custom 5 Pin Electrical Plugs Bullhorn Creation

In electrical engineering, secure and efficient connections play a crucial role in ensuring optimal system performance. Among the various types of connectors, custom 5-pin electrical plugs—especially the innovative “Bullhorn” design—offer exceptional reliability. These specialized connectors are engineered to meet the demands of industries requiring high durability, superior conductivity, and enhanced safety. Their robust construction makes them indispensable in advanced electrical systems across multiple industrial applications, where precision and performance are non-negotiable.

Understanding Custom 5-Pin Electrical Plugs

Custom 5-pin electrical plugs are specialized connectors designed to support five individual electrical connections within a single unit. These versatile plugs effectively transmit electricity, information alerts, or a mixture of each, making them essential in various industries. Unlike typical, off-the-shelf connectors, custom five-pin plugs are especially engineered to satisfy unique operational requirements, making sure choicest performance, protection, and reliability.

Key Features of Custom five-Pin Electrical Plugs

- Multi-Function Connectivity – Supports simultaneous power and data transmission.

- High Durability – Constructed from premium materials to withstand harsh environments.

- Custom Engineering – Designed to fit specific industry needs for maximum efficiency.

- Space-Saving Design – Compact and adaptable for tight installations.

- The Role of Bullhorn Creation in Custom Plug Design

- Bullhorn creation refers to an advanced approach in designing and manufacturing custom 5-pin electrical plugs. This method involves a collaborative process between engineers, designers, and clients to develop a connector that meets exact functional and environmental requirements.

The Bullhorn Creation Process

- Needs Assessment – Engineers analyze electrical load, environmental factors, and system compatibility.

- Prototyping & Testing – A prototype is developed and tested for feasibility and performance.

- Material Selection – High-quality, durable materials are chosen for longevity.

- Precision Manufacturing – Advanced techniques ensure uniformity and reliability.

- Quality Assurance – Each plug undergoes rigorous testing to guarantee safety and efficiency.

- Applications of Custom 5-Pin Electrical Plugs

- Custom five-pin electric plugs play a critical function in numerous industries, wherein their reliability and adaptableness make them vital.

Automotive Industry

- Lighting Systems – Enhancing modern LED vehicle lighting.

- Sensor Integration – Supporting engine diagnostics and safety features.

- Audio Components – Ensuring seamless sound transmission.

- Industrial Machinery

- Control Panels – Facilitating efficient machine operation.

- Sensor Networks – Connecting temperature, pressure, and environmental monitoring devices.

- Heavy Equipment – Powering large-scale machinery in demanding conditions.

- By leveraging custom 5-pin electrical plugs designed through bullhorn creation, industries can achieve enhanced performance, safety, and longevity in their electrical systems.

- Advantages of Custom 5-Pin Electrical Plugs

- Custom 5-pin electrical plugs provide unmatched flexibility, allowing for tailored solutions that meet specific industry needs. Unlike standard connectors, these customized plugs are designed to enhance functionality across various applications.

- Improved safety is among the biggest advantages. Custom designs eliminate compatibility issues, reducing the risk of electrical malfunctions and ensuring secure connections.

- Another key advantage is durability. Built with fantastic substances suitable for their meant environments, those plugs offer lengthy-lasting performance, even in demanding commercial conditions.

- Beyond capability, aesthetic customization is an added perk.

- Companies can incorporate branding elements into their plug designs, reinforcing their professional identity while maintaining high performance.

- Custom plugs also lead to improved efficiency. Whether through better conductivity, resistance to environmental stressors, or optimized configurations, these specialized connectors enhance overall system reliability.

How Custom 5-Pin Electrical Plugs Are Designed

- The creation of a custom 5-pin electrical plug bullhorn follows a structured and collaborative process to ensure precision and performance.

- Consultation & Requirement Analysis – Engineers work closely with clients to understand their needs, including electrical specifications, operational environments, and intended use cases.

- Technical Design & Material Selection – Experts develop detailed schematics while choosing materials that enhance durability, conductivity, and safety.

- Prototype Development

- This step-by-step process guarantees that each custom plug meets exact performance expectations while prioritizing safety and efficiency.

Key Considerations When Designing a Custom Plug

Several factors ought to be taken into consideration when designing a custom 5-pin electrical plug to make certain reliability and functionality

Top Features & Designs for Custom 5-Pin Electrical Plugs

- The best custom 5-pin electrical plugs incorporate features that enhance usability and longevity. Some standout design elements include:

- Ergonomic Grip – Ensures ease of handling and convenient connection.

- High-Quality Materials – Increases durability and resistance to put on and tear.

- Weatherproofing – Provides protection against moisture, dust, and excessive temperatures.

- Aesthetic Customization – Allows corporations to healthy plugs with branding or enterprise-specific coloration codes.

- Built-in Saf

- ety Features – Fuses, insulation reinforcements, and overload protection mechanisms add an extra layer of security.

- Modular Design – Enables easy upgrades without replacing the entire plug, making it cost-effective for evolving technology needs.

- By integrating these elements, custom 5-pin plugs not only perform efficiently but also enhance user experience across various settings.

- Essential Components and Tools for Assembling a Custom Plug

- Before you dive into your challenge, it’s vital to acquire the proper substances and gear to make sure a smooth and efficient meeting. Here’s a checklist of the ought to-have additives and device for building a custom plug.

Key Components

- Outer Casing: This acts as the protective shell, safeguarding the internal components from wear, tear, and environmental damage.

- Conductive Materials: These are the pathways for transmitting strength or alerts. High-best metals, like copper, are commonly favored for ideal conductivity.

- Insulating Layers: These materials lessen the danger of quick circuits, overheating, and electrical interference.

- Connection Cables: Choose the proper gauge primarily based for your venture’s strength or signal transmission desires to ensure proper overall performance.

- Tools You’ll Need

- Thermal Joining Device (e.G., Soldering Iron): A ought to-have device for securely connecting additives and making sure reliable electric float.

- Wire Strippers: Used to securely take away insulation from wires with out detrimental the conductor under.

- Compression Tools: Essential for crimping and securing cable ends to connectors or terminals.

- Diagnostic Meter: A crucial tool for verifying electrical continuity and normal capability before finishing your undertaking.

- Protective Wrapping Materials (e.G., Heat Shrink Tubing or Electrical Tape): These materials decorate durability and guard your connections from environmental factors along with moisture and dirt.

- Planning and Structuring Your Custom Plug Design

- Designing the Layout

- Contact Placement: Plan the arrangement of the five contact points within your plug. Decide whether you want them in a row, circular formation, or another configuration based on your design needs.

- Wire Selection: Choose wires that match the electrical demands of your project. For high currents, thicker wires are necessary, while shielded wires might be needed for precision signal transmission.

- Outer Durability: Ensure your casing is rugged enough to withstand mechanical stress or outdoor conditions if necessary.

- Functional Planning

- Pin Functions: Outline the specific role of each pin. For example:

- Pin 1 could serve as the ground connection.

- Pins 2 and 3 may carry power.

- Pins 4 and 5 could handle data signals.

- Make sure your design aligns with your specific functional requirements and matches the standards for your project, especially in terms of electrical safety and performance.

- By following this guide, you can ensure that your custom 5-pin plug is assembled efficiently, functions flawlessly, and meets all safety and performance standards. Whether you’re working on a complex project or a simple application, the right components and planning make all the difference.

- Design Considerations for Bullhorn Applications

- When designing custom 5-pin electrical plugs for bullhorn applications, engineers prioritize several key factors to ensure optimal performance and reliability:

Compact

- Creating a custom 5-pin electrical plug for bullhorn applications involves several important steps to ensure precision, functionality, and durability:

- Initial Consultation: Engineers start by way of information the unique electric needs of the bullhorn, contemplating elements including strength necessities and environmental conditions.

- Material Selection: Materials are carefully selected for their weatherproof and effect-resistant properties, making sure that the plugs can carry out reliably in various situations.

- Prototyping: A prototype of the plug is created to make sure that the design aligns with the bullhorn’s specifications and requirements.

- Testing: The custom plug undergoes rigorous checking out to satisfy industry standards for safety, durability, and overall performance before it’s far approved for use.

- Applications of Custom 5 Pin Electrical Plugs

- Custom five-pin electrical plugs have a wide variety of applications throughout more than one industries, where their reliability and performance are essential.

Automotive Industry

- In cars, those plugs are crucial for connecting complicated electric structures, which includes:

- Lighting Systems: Ensuring efficient electricity distribution to diverse lights additives.

- Sensors: Providing dependable signal transmission for protection capabilities, including collision detection and adaptive cruise manipulate.

- Industrial Machinery

- In commercial settings, custom 5-pin plugs are essential for:

- Heavy-Duty Equipment: Keeping system going for walks smoothly and reliably in harsh, worrying environments.

- Automation Systems: Enabling seamless information and electricity connectivity in computerized equipment.

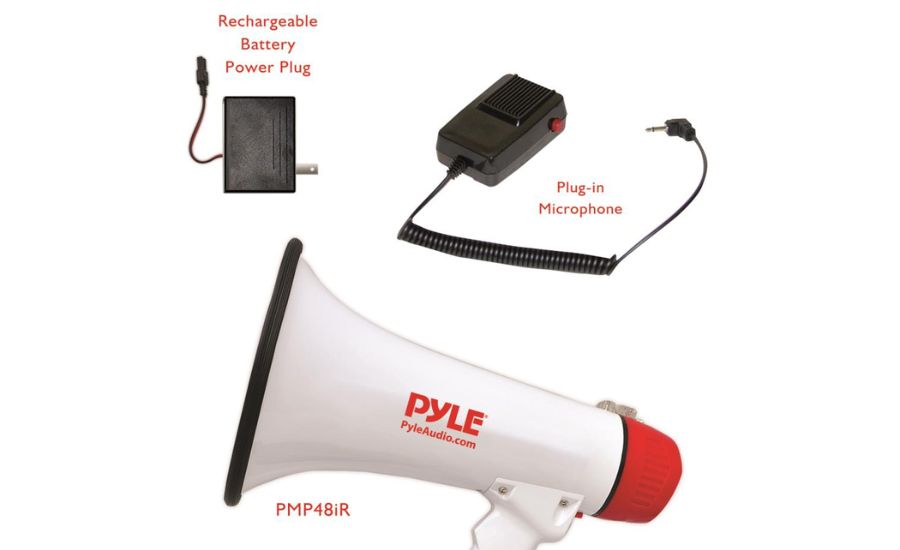

Audio Equipment

- For devices like bullhorns and public address systems, these plugs ensure:

- Clear Audio Transmission: Minimizing signal interference for high-quality sound.

- Durability: Withstanding the wear and tear common in live events and public spaces.

- Consumer Electronics

- Custom 5-pin plugs also serve a variety of consumer electronics, such as gaming consoles and home appliances, by offering tailored solutions for improved functionality and ease of use.

Advantages of Custom 5 Pin Electrical Plugs

- The use of custom 5-pin electrical plugs brings several benefits, ensuring that devices function optimally:

- Enhanced Reliability: Designed mainly to fulfill the precise electrical needs of every tool, custom plugs minimize the chance of faults or malfunctions.

- Increased Durability: Made from top notch substances, custom plugs are proof against put on, corrosion, and environmental pressure, making sure lengthy-lasting performance.

- Tailored Functionality: Custom configurations allow for particular manipulate over strength distribution, statistics transmission, and different essential functions, ensuring top-rated performance in every application.

How to Choose the Ideal Custom 5-Pin Electrical Plugs for Bullhorns

Selecting the proper custom five-pin electric plug is critical for ensuring the optimum performance and sturdiness of your bullhorn. To assist you make an informed desire, remember these key factors:

1. Compatibility

The first step is making sure that the plug is absolutely like minded along with your bullhorn’s electric and purposeful desires. A custom five-pin plug need to be designed in particular to meet the precise requirements of your tool, making sure seamless operation and preventing any performance problems.

2. Quality Assurance

Always choose plugs from trusted manufacturers known for their commitment to quality and reliability. High-quality custom plugs, carefully crafted during the bullhorn creation process, are less likely to malfunction, providing consistent and dependable performance over time.

3. Customization Options

Look for manufacturers that offer customization tailored in your specific desires. Whether you require superior sturdiness for harsh environments, extra features like waterproofing, or cloth alternatives, custom five-pin plugs provide the ability to meet a huge variety of demands.

This level of customization ensures the plug works seamlessly with your bullhorn and extends its operational life.

Final Thoughts on Custom 5-Pin Electrical Plugs Bullhorn Creation

In summary, custom 5-pin electrical plugs, especially those designed for bullhorn packages, are crucial additives in ensuring reliable, long lasting, and efficient electric systems. These specialised connectors are tailored to fulfill the unique desires of industries together with automotive, industrial equipment, and audio device, offering superior overall performance in traumatic environments. The precision layout, terrific substances, and collaborative technique during the bullhorn introduction process allow manufacturers to create connectors that no longer only meet but exceed enterprise standards for protection, capability, and durability.

By choosing the right custom five-pin plug, you ensure seamless integration along with your electric machine, limit downtime, and improve typical efficiency. Whether you are working on a complicated machine or a simple plug-and-play application, taking the time to choose the precise plug could make a sizeable distinction within the overall performance and reliability of your equipment.

Key Facts About Custom 5-Pin Electrical Plugs for Bullhorns

Precision Engineering: Custom 5-pin plugs are designed to meet specific electric and environmental necessities, making sure most suitable performance.

Durability: These plugs are crafted from top notch materials, supplying resistance to put on, corrosion, and harsh conditions.

Versatility: They assist both power and facts transmission, making them critical in a wide variety of industries.

Customization: Each plug can be tailored to meet unique desires, together with weatherproofing, brought durability, and progressed protection capabilities.

Safety Assurance: Rigorous attempting out is finished at every diploma to guarantee that the plugs meet enterprise requirements for protection, reliability, and capability.

Frequently Asked Questions (FAQs)

1. What are the key blessings of the use of custom 5-pin electrical plugs?

Custom 5-pin plugs offer enhanced reliability, improved durability, and tailored functionality for specific applications. They ensure better performance by addressing unique requirements such as weather resistance, data transmission, and power delivery.

2. Can custom 5-pin electrical plugs be used in harsh environments?

Yes, these plugs are particularly designed for durability in difficult environments. They may be made with climate-resistant and impact-resistant substances to resist excessive temperatures, moisture, and bodily put on.

3. How does the bullhorn creation process work?

Bullhorn creation is a collaborative design and manufacturing process involving engineers, designers, and clients. It focuses on ensuring the custom 5-pin plug meets the electrical requirements, environmental conditions, and functional needs of the application.

4. What industries benefit the most from custom 5-pin plugs?

Custom five-pin electrical plugs are used across various industries, together with automobile (for lights and sensors), commercial equipment (for manipulate panels and automation structures), audio system (for sound transmission), and consumer electronics (for gaming consoles and domestic appliances).

5. What factors must be taken into consideration whilst designing a custom 5-pin electrical plug?

Key factors include compatibility with existing structures, the supposed environment (e.G., outdoor or commercial use), electric load, protection functions, and ease of set up. It’s essential to select first rate materials for conductivity, durability, and insulation to make certain superior performance.

6. How do I choose the right custom 5-pin electrical plug for my bullhorn?

When selecting a plug, ensure it meets the specific electrical and functional requirements of your bullhorn, such as power or data transmission. Prioritize manufacturers known for quality and offer customization options tailored to your needs.

7. Can custom 5-pin electric plugs be upgraded within the destiny?

Yes, many custom five-pin plugs function modular designs that permit for easy improvements while not having a complete replacement, which makes them fee-powerful and adaptable to evolving technology.

By preserving these records and suggestions in thoughts, you may hopefully layout, pick, and put in force custom 5-pin electrical plugs for any project, understanding that they will provide dependable and long-lasting overall performance.

Read More About Gadget At: Prostavivecolibrim